Produktbeschreibung

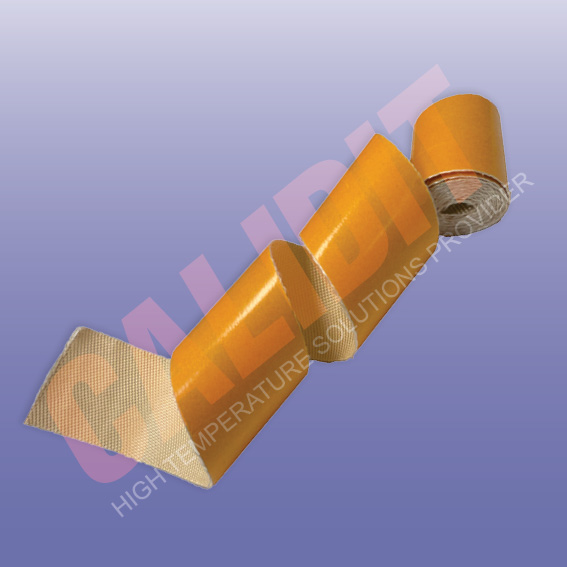

Silica fiber webbing tape is renowned for its excellent thermal insulation properties and can withstand temperatures up to 1000°C, making it suitable for high-temperature applications such as furnaces, kiln cars, exhaust insulation, and boiler sealing.

Originally used in the construction industry for reinforcing and waterproofing timber, fiber tape has become a staple due to its strength and durability from synthetic fibers. It effectively reinforces materials like concrete, wood, and metal, and finds use in the automotive and crafting industries. Its versatility makes it an excellent choice for DIY projects and repairs.

Silica webbing tape is manufactured by weaving textured or non-textured continuous filament S-TEX silica yarn, combining outstanding temperature resistance and strength. It causes minimal irritation and withstands continuous temperatures up to 1000°C under optimal conditions. Unlike ceramic fiber webbing, silica tape does not vitrify at lower temperatures and is recommended as a substitute. It also exhibits excellent chemical stability, resisting attacks from organic agents, water, and hot acids (excluding hydrofluoric acid). The tape is incombustible according to DIN 4102 A2 standards and can be produced up to 500mm wide.

Silica woven tapes are intended for high-temperature applications, providing continuous service up to 982°C (1800°F). This high-temperature woven tape is used for equipment fire protection, heat insulation of pipe hoses and electric cables, and resists splattering of welding and molten metal.

Features:

- Superior Thermal Insulation

- High Temperature Resistance (up to 1000°C)

- Strong and Durable

- Excellent Chemical Stability

- Minimal Irritation

- Incombustible (DIN 4102 A2 Standards)

- Preshrunk with Minimal Shrinkage

- Pressure Sensitive Adhesive Backing (for certain variants)

Applications:

- Exhaust Insulation

- Boiler Sealing

- Reinforcing and Waterproofing Timber

- DIY Projects and Repairs

- Equipment Fire Protection

- Heat Insulation for Pipe Hoses and Electric Cables

- Welding and Molten Metal Protection

- Gaskets and Sealing Joints