Produktbeschreibung

Polycrystalline ceramic fiber is an advanced material known for its ease of processing into ceramic textiles due to its metallic oxide composition. This continuous fiber exhibits superior mechanical and thermal performance compared to traditional fibrous materials like aramid, silica, quartz, and glass.

Body: Ceramic tapes are capable of withstanding operating temperatures up to 1100°C, making them ideal for insulating and protecting cables, tubes, and pipes, as well as reinforcing packaged products. A heat-cleaned coated version is available to reduce irritations and minimize flying fibers and smoke during high-temperature exposure.

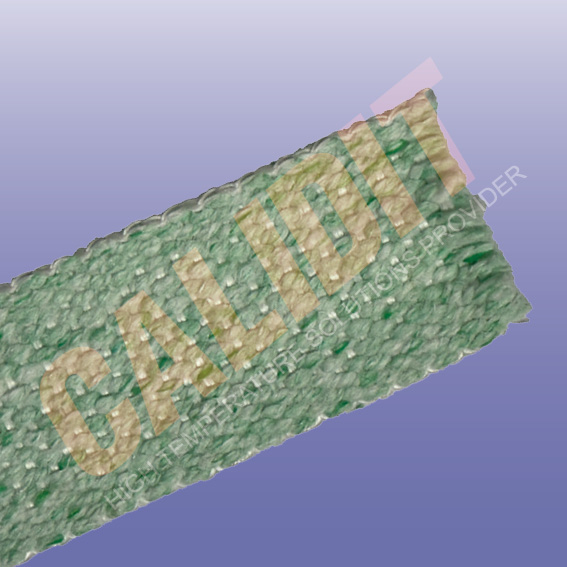

Ceramic fiber tape, offering flexibility and mechanical resistance, can be used continuously at temperatures up to 650°C (glass-fiber reinforced) or 1050°C (Inconel reinforced). It contains about 20% organic binders to facilitate the carding process, which burn off at low temperatures without affecting the special glass fibers. On request, the tape can be impregnated with graphite for increased lubrication.

Woven from high-quality ceramic fiber yarn, these tapes are lined with fiberglass thread or optionally reinforced with Inconel or alloy steel tubes. Despite the presence of binder material, which burns off at lower temperatures, the tape retains its excellent insulation properties. It is widely used in thermal installations and heat-conductive systems, including welding, foundry work, aluminum and steel mills, boiler insulation and sealing, shipyards, refineries, power plants, and chemical plants.

Features:

- Superior Thermal Insulation

- High Temperature Resistance (up to 1100°C)

- Flexibility and Mechanical Resistance

- Reduced Irritation (heat-cleaned version)

- Optional Graphite Impregnation

- High-Quality Yarn Weaving

- Minimal Impact of Binder Material on Insulation Properties

Applications:

- Thermal Insulation

- Pipe and Exhaust Insulation

- Electrical Insulation

- Reinforcing Packaged Products

- Welding, Foundry Work

- Boiler Insulation and Sealing

- Wrapping Wires, Cables, and Pipes

- Gaskets